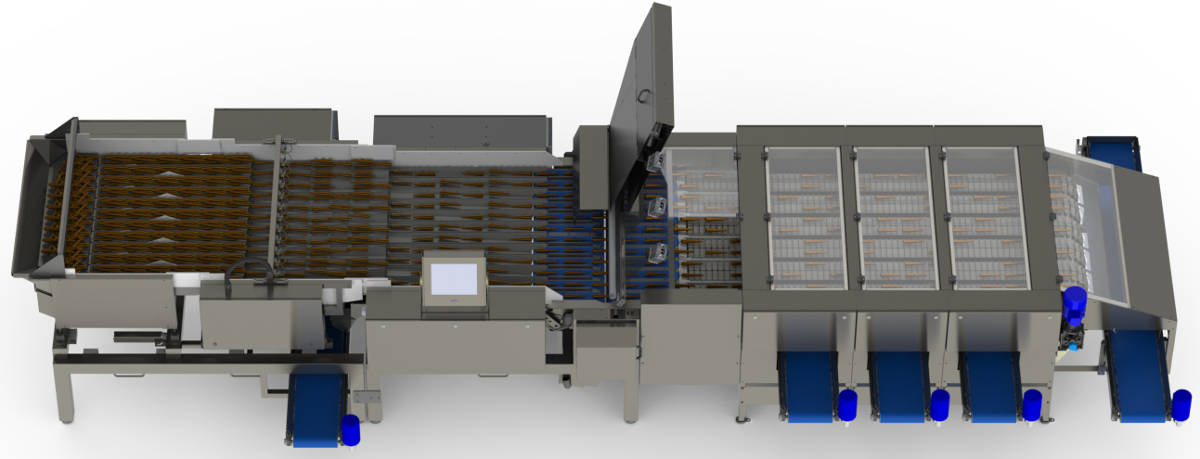

WASH & GRADING

Always an EMVE-production

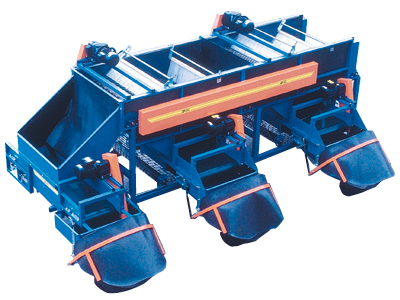

The washing- and gradinglines represents a significant part of our total production. They vary both in size and application, but the backbone is always an EMVE production. These type of applications are actually combinations of several different machines. Here we coarse and finegrade potatoes and vegetables and after that they are washed before off to final packaging and distribution to stores and customers.

Security without interruption

We are not satisfied until we receive an OK from our customers, ”now the line is working optimally”. However, cooperation with our customers doesn´t end here. On the contrary, it’s now that we show why we deserve our solid reputation as a responsible supplier. We offer extensive maintenance and development agreements to our customers. This is the kind of security that assures them of continuous production without unpleasant and costly interruptions.

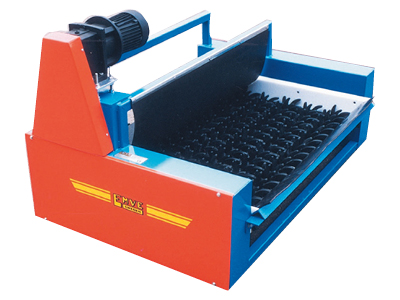

Soil Extractor SE B

Soil Extractor SE D, SE S

The rollers are driven by a geared motor. Soil extractors are available in various widths and with differing numbers of rollers, to meet different capacity requirements

Soil Extractor SE CC

Brushing Machine BM

Roller Table RT

Belt Grader G B

Belt Grader G Bx2

Roller Grader G D

Grader Mod RT/PT

Lenght graders

Varible vibrations for optimal grading. The opening gap is adjustable. Screen with round holes is produced only for broken pieces.

Roller grader G HR

Rollergrader Kerian

by conveyors to boxes or further processing. The grading is done very silent and with high capacity. Especially good for grading long sized products. For best function the grader needs an aligning table before the grader.

Stem and roots separator SE SC

The product is fed on the diagonal conveyor. The product slides down while stems and roots are drawn upwards over the edge. The diagonal conveyor can be manufactured with small spikes, alternative with larger/longer spikes. Inclination can be adjusted manual or via an electric actuator. Manufactured in stainless, or mild steel painted.

Floating object remover WE EF

The machine with options as pump and water spraying system at outfeed. Produced in stainless blasted steel. Product is fed in the backend of the machine, and floating objects are scraped sideways and slides over a screen to be separated from as much water as possible. Floating objects can fall directly in to customers box or similar. Left or right hand version to be set before order. Can be produced in different versions from 1-50 ton/hour. Options as pump, levelindicator, freshwater spraying and productfeeder can be provided.

Destoners

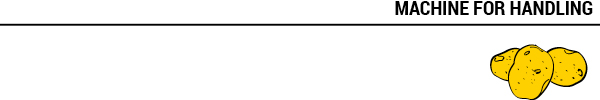

Drum Washer WE DW

They are fitted with perforated steel plate drums with adjustable carriers and outlets via adjustable spiral screws in the outlet cone, to give gentle unloading with no fall heights. A choice is available between “dry washing” or washing in a water bath. Washers are equipped with rinsing nozzles in the drum, waste water valve and a hatch cover that can be removed for cleaning purposes. Suspension and drive is via belt, to give quiet, gentle operation. Digital frequency control of the worm gear drive for continuous adjustment of speed of rotation and reverse is a standard feature.

Washer WE DW1200ES

The drum is adjustable up and down, and together with the adjustable gate at outfeed, the adjustable water level and drum speed, it gives full flexibilty in adjusting the washers performance. By easily lifting the drum it also gives a very short change over time to next product. Incl. outfeed elevator with fresh water spraying. Agitator i bassin for antisedimentation, and pump for automatic water level control. Door and and gates one the sides for acess to cleaning and service when needed. Equipped with EMVE watercleaning system Akva-sep, with recycling and minimal use of fresh water conumption.

Capacity. 5-30 ton/tim.

Dimension (LxW) = 6,3×1,8 m. Infeed h=. h=2,2 m, outfeed =2,3 m.

Always produced in stainless steel, marble blasted.

Complete electrical panel.

Polisher WE PM D

For polishing of potato, carrot, parsnips etc.

12, 14 or 18 brushes. Lengths 2 – 2.5 – 3 and 3.5 m. Different length and stiffness of the brushes.

Adjustable speed on the drum and rollers.

Adjustable tilt on the drum, and the height of the output.

Direct drive of each roller brush. No belt drive.

Easily removable rollers without removing the bearings.

Polisher WE BP

drum and brushers are adjustable with totally 3 motors. Simple construction and rotation of the drum with only 2 pc. powerbelts. Brushers/shafts can easily be lifted out sideways from the machine for service. Brushsegments can be taken off without taking off the bearings or pulley.

The tripplesealed protected bearings are easily lubricated due to open construction. The bearings are protected by cups filled with grease, to prevent water from getting in. The polisher can be adjusted by angle of the drum, the outfeed gate, the drum speed, the brush speed and added water to get optimal polishing.

Different versions for water recycling and cleaning can be delivered.

Hydrocooler WE DW 1200

For cooling of potato, carrot etc.

Perforated drum with internal spiral screw to feed the product, first in – first out. Hydrocooler is made of stainless steel. Including doors on each side for cleaning. Adjustable water height, temperatur and holdingtime.

Drying Machine WE DM

Optical sorter – Carrot

C-UHD

Optical sorter – Potatoe

P-UHD